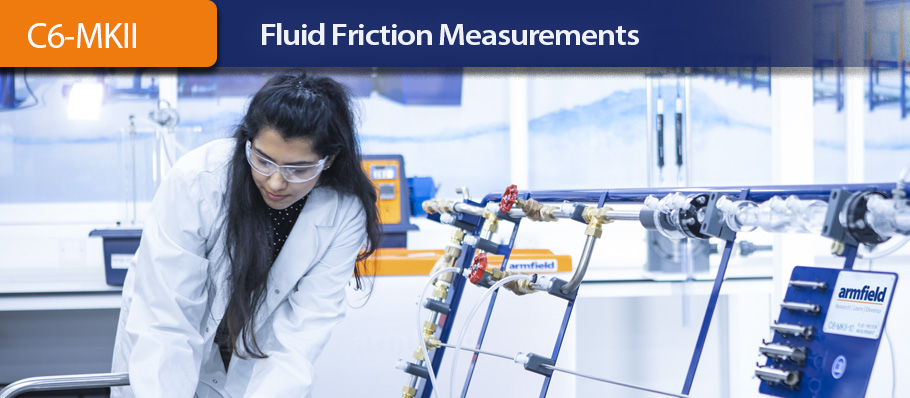

The Armfield C6-MKII-10 Fluid Friction Measurements unit

Provides facilities for the detailed study of fluid friction head losses, which occur when an incompressible fluid flows through pipes, fittings and flow metering devices.

A wide range of measurements, demonstrations and training exercises are possible with the equipment:

· Confirming the relationship between head loss due to fluid friction and velocity for flow of water

· Determining the head loss associated with flow through a variety of standard pipe fittings

· Determining the relationship between pipe friction coefficients and Reynolds’ number for flow through a pipe with roughened bore

· Demonstrating the application of differential head devices in the measurement of flow rate and velocity

· Providing practical training of pressure measurement techniques

· Enhancing understanding of the hydraulic principles involved through the use of complementary computer software

See more at www.armfield.co.uk